Alumina is a key component in the production of aluminum, and it is the most widely used industrial oxide in the world. It is a white, powdery substance that is derived from bauxite, a mineral that is found in abundance in many parts of the world. While alumina is essential to the production of aluminum, its production can also have negative environmental impacts. In this article, we will explore the production of alumina, the problems associated with its production, and the ways in which these problems can be mitigated.

What Is Alumina?

It is also known as aluminum oxide (Al2O3), is a chemical compound that is derived from bauxite. Bauxite is a mineral that is primarily composed of aluminum hydroxides, along with other minerals such as iron oxide and silica. To produce alumina, bauxite is first refined into alumina trihydrate (Al(OH)3), which is then calcined (heated) to remove the water and produce alumina.

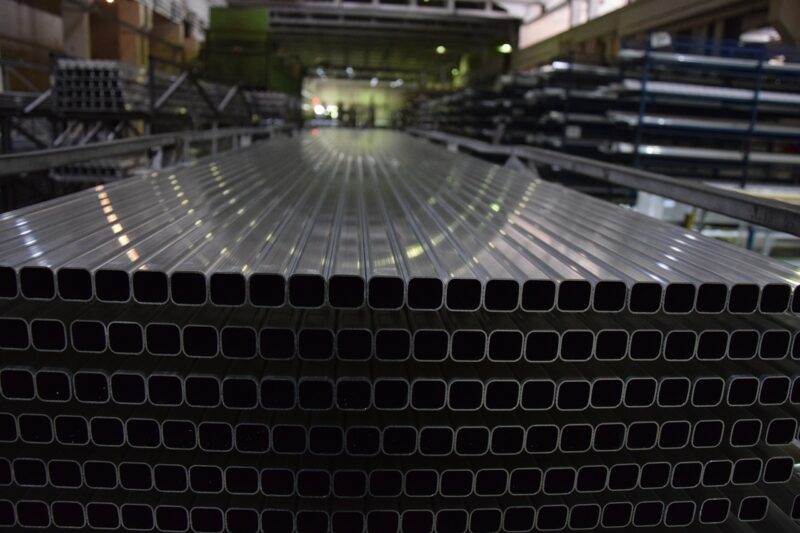

It is a white, powdery substance that is used in a wide range of industrial applications. Its most important use is in the production of aluminum, where it is used as a feedstock for the electrolytic process that produces aluminum metal. Alumina is also used in the production of ceramics, refractories, abrasives, and other industrial materials.

Alumina Production:

The production of alumina begins with the mining and refining of bauxite. Bauxite is typically mined in open-pit mines, where it is extracted using heavy machinery. Once the bauxite has been mined, it is transported to a refinery, where it is processed into alumina.

The refining process involves several stages. First, the bauxite is crushed and washed to remove impurities. The resulting slurry is then heated and mixed with caustic soda (NaOH) to produce alumina trihydrate. The alumina trihydrate is then filtered and washed to remove impurities, and finally, it is calcined (heated) to remove the water and produce alumina.

The production of alumina is a highly energy-intensive process, and it is estimated that approximately 3% of the world’s electricity is consumed in the production of alumina.

Problems Associated with Alumina Production:

While it is essential to the production of aluminum and many other industrial applications, its production can also have negative environmental impacts. One of the primary concerns associated with alumina production is the generation of red mud.

Red mud is a byproduct of the refining process, and it is produced when the bauxite is mixed with caustic soda. Red mud is a highly alkaline substance that contains a variety of toxic metals, including arsenic, lead, and mercury. It also contains radioactive materials such as thorium and uranium.

Red mud can be difficult to dispose of safely, and it is often stored in large impoundments that can pose a risk to the environment and human health. There have been several high-profile incidents in recent years where red mud impoundments have failed, resulting in the release of large amounts of toxic waste into the surrounding environment.

Mitigating the Problems Associated with Alumina Production:

There are several ways in which the problems associated with alumina production can be mitigated. One approach is to develop alternative methods of producing alumina that generate less red mud or eliminate it altogether.

One such alternative method is the use of high-pressure digestion (HPD) technology. HPD technology involves the use of high-pressure steam to dissolve the alumina from the bauxite, rather than using caustic soda. This process generates significantly less red mud and produces a higher-quality alumina product.

Another approach to mitigating the problems associated with alumina production is to improve the efficiency of the refining process. This can be achieved through the use of advanced technologies and process optimization.

One technology that has been shown to improve the efficiency of alumina production is the use of digital twins. Digital twins are virtual models of a physical process or system that can be used to simulate and optimize its performance. By using digital twins to model the refining process, it is possible to identify areas for improvement and optimize the process parameters to reduce energy consumption and waste generation.

In addition to improving the efficiency of the refining process, it is also important to develop safe and effective methods for disposing of red mud. One approach that has been proposed is the use of red mud as a feedstock for the production of construction materials.

Red mud contains high levels of alumina and other minerals that can be used to produce materials such as concrete and bricks. By using red mud as a feedstock for construction materials, it is possible to reduce the amount of waste generated by the refining process and create a value-added product.

Conclusion:

It is a key component in the production of aluminum and other industrial materials, but its production can have negative environmental impacts. The primary concern associated with alumina production is the generation of red mud, a highly alkaline substance that contains a variety of toxic metals and radioactive materials.

To mitigate the problems associated with alumina production, it is important to develop alternative methods of producing alumina that generate less red mud or eliminate it altogether. This can be achieved through the use of advanced technologies such as high-pressure digestion and digital twins, as well as through the development of safe and effective methods for disposing of red mud.

By addressing the environmental impacts of its production, it is possible to create a more sustainable and responsible industry that can meet the growing demand for aluminum and other industrial materials while protecting the environment and human health.

Similar Articles

- Waterspout: A Guide to Understanding this Weather Phenomenon

- Beat the Heat: Tips for Handling Really Hot Weather

Frequently Asked Questions About Alumina

Q: What is alumina used for?

A: It is primarily used as a feedstock for the production of aluminum metal, but it is also used in a variety of other industrial applications, such as ceramics, abrasives, refractories, and catalysts.

Q: What is red mud?

A: Red mud is a highly alkaline waste material that is generated during the refining of bauxite into alumina. It contains a variety of toxic metals and radioactive materials and can have negative environmental impacts if not properly managed.

Q: How is alumina produced?

A: It is produced through a process called the Bayer process, which involves the refining of bauxite ore using caustic soda to extract the alumina. The process generates red mud as a waste material.

Q: What are the environmental impacts of alumina production?

A: The primary environmental concern associated with its production is the generation of red mud, which can contaminate soil and water if not properly managed. The refining process also consumes large amounts of energy and can generate greenhouse gas emissions.

Q: What is high-pressure digestion?

A: High-pressure digestion is a technology that involves using high-pressure steam to extract it from bauxite ore. It is a more efficient and environmentally friendly alternative to the traditional Bayer process.

Q: What are digital twins?

A: Digital twins are virtual models of physical processes or systems that can be used to simulate and optimize their performance. They can be used to improve the efficiency and sustainability of its production by identifying areas for improvement and optimizing process parameters.

Q: How can red mud be disposed of safely?

A: Red mud can be disposed of safely through a variety of methods, such as landfilling, impoundment, or reuse as a feedstock for the production of construction materials. The key is to ensure that proper precautions are taken to prevent contamination of soil and water.